12

2025

-

06

China Hydraulic Breaker Industry Report: From Import Dependence to Global Leadership

1.What is a Hydraulic Breaker?

A hydraulic breaker,also known as a hydraulic hammer, is an excavator attachment that converts hydraulic energy into mechanical impact energy.It comprises a cylinder,piston,control valve,accumulator,chisel,and housing.With the piston’s rapid reciprocating motion,it efficiently breaks through concrete,rock,and steel structures.Key components include:

• Front/Rear Cylinder

• Piston&Control Valve

• Accumulator&Chisel(Tool Bit)

Classification by Chisel Diameter:

Type Chisel Size(mm)Applications

|

Small |

40–70 |

Urban construction, landscaping |

|

Medium |

75–145 |

Building demolition, road repair |

|

Large |

≥150 |

Mining, quarrying (50% gross margin) |

2.Key Applications

Hydraulic breakers are widely used in:

✔Construction&Demolition(concrete crushing,bridge repair)

✔Mining&Tunneling(rock fragmentation,ore extraction)

✔Road/Railway Maintenance(pavement breaking,track bed preparation)

✔Metallurgy(slag processing)

Growing demand in Southeast Asia,Africa,and Latin America due to infrastructure development.

As a multifunctional attachment,it significantly expands the working range of excavators and loaders.

3.Development History of China’s Hydraulic Breaker Industry

China's hydraulic breaker industry began in the 1990s,lagging behind Japan and Korea.During the 2000s,infrastructure expansion spurred high domestic demand,but local manufacturers struggled with low capacity and limited product range.

Since 2016,under national strategies promoting structural adjustment and technological upgrading,the sector has entered a phase of accelerated growth.Breaker technology has advanced steadily,driven by R&D and market feedback.

Phase 1:Early Stage(1990s)

• Relied on imports(Japanese/Korean brands dominated).

Phase 2:Rapid Growth(2000–2015)

• Domestic demand surged,but local products lagged in technology(imports held 60%market share).

Phase 3:Domestic Takeover(2016–Present)

• Government policies("Industrial Upgrading")boosted R&D.

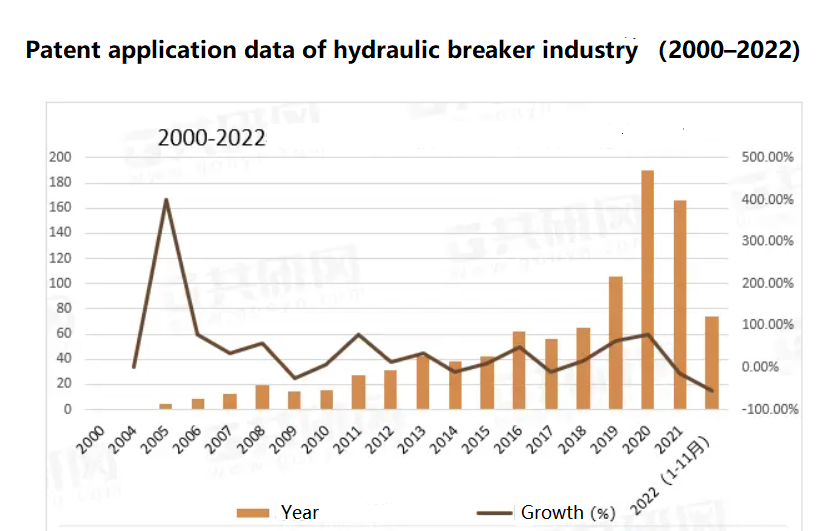

• Patent filings peaked in 2020(190 patents,+79.25%YoY).

• Imports dropped to 20%share as Chinese brands improved.

In 2020,the number of patent applications in China's hydraulic breaker industry reached 190,representing a year-on-year growth of 79.25%.There was a slight decrease in 2021,and from January to November 2022,the industry had already completed 74 patent applications.

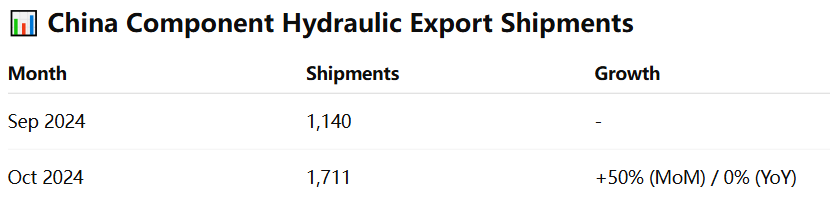

According to Volza's China Export data,China exported 24,536 shipments of Component Hydraulic from Nov 2023 to Oct 2024(TTM).These exports were made by 2,012 China Exporters to 1,922 Buyers,marking a growth rate of 30%compared to the preceding twelve months.

Within this period,in Oct 2024 alone,1,711 Component Hydraulic export shipments were made from China.This marks a year-on-year growth of 0%compared to Oct 2023,and a 50%sequential growth from Sep 2024.

4.Competitive Advantages of Chinese Hydraulic Breakers

✅Technological Innovation

•Zhejiang(168 patents),Shandong(164 patents)lead in R&D.Smart features(IoT monitoring,energy-saving designs)emerging.

In 2020,the number of patent applications in China's hydraulic breaker industry reached 190,representing a year-on-year growth of 79.25%.There was a slight decrease in 2021,and from January to November 2022,the industry had already completed 74 patent applications.

✅Cost&Supply Chain Efficiency

•Lower production costs than EU/US brands.

•China became the world’s top exporter in 2023(Vietnam,Indonesia,Russia are key markets).

✅Policy&Market Demand

•"Belt&Road"projects drive growth.

•Domestic market to reach¥10.48B by 2030(CAGR 3.91%).

5.Market Performance&Export Trends

📊Domestic Market Share

•Local brands now hold 80%(vs.40%in 2010).

•Top players:Eddie Precision,Jingtian Intelligence.

🌍Global Exports(2023)

•Top Destinations:

o Southeast Asia(Vietnam,Indonesia)

o North America(USA,Canada)

o Oceania(Australia)

o Russia/Eastern Europe

•Challenge:Still heavily reliant on OEM production(branding needs improvement).

6.Quality Assurance&Future Outlook

🔧Improved Product Quality

•Durability:High-strength alloy materials.

•Eco-Friendly:Low noise/vibration compliance.

•Smart Tech:Sensor-based precision control.

🚀Future Trends

•Shift from"low-cost"to"high-tech+brand-driven"growth.

•Expansion into premium global markets.

Conclusion:Quality Guaranteed by China-Made

China’s hydraulic breaker industry is advancing from“Made in China”to“Innovated in China.”With reliable performance,competitive pricing,and increasing global recognition,Chinese breakers have become the trusted choice worldwide.

Related News