01

2025

-

04

Sizing the Hydraulic Breaker

Hydraulic Breaker Sizing Guide When selecting a hydraulic breaker, two key factors must be considered: Carrier Operating Weight 1. Based on Carrier Weight 2. Based on Type of Application ■ Small Breakers (≤1,000 ft·lb / 1350 J) Ideal for light-duty jobs like breaking concrete. ■ Medium Breakers (1,500–4,000 ft·lb / 2000–5400 J) Suited for concrete and light rock applications. ■ Large Breakers (≥4,000 ft·lb / 5400+ J) Used for hard rock and high-production requirements. 3. Application Examples ■ Breaking Oversized Material For 4 yd³ hard rock (20,000+ psi): use ≥7,500 ft·lb breaker For 2 yd³ limestone (<20,000 psi): use 3,000–5,000 ft·lb breaker ■ Trenching In medium rock (e.g., limestone): 3,000–5,000 ft·lb In hard rock: 7,500–10,000 ft·lb

Sizing the Hydraulic Breaker

When sizing the breaker to the machine, two key points should be given careful consideration:

Machine operating weight

Hydraulic system capabilities

With the correct carrier weight, ROCKA offers hydraulic breakers that are designed to break any

material that the machine can handle. Sizing the breaker by carrier hydraulics gives the operator a

carrier/breaker combination designed to optimize the system efficiency, thereby reducing heat

generation and eliminating power loss.

The following steps will result in a well-matched installation. This manual will not cover all types of

applications, so for assistance in any unusual situations please contact your rocka representative.

Based on Carrier Weight

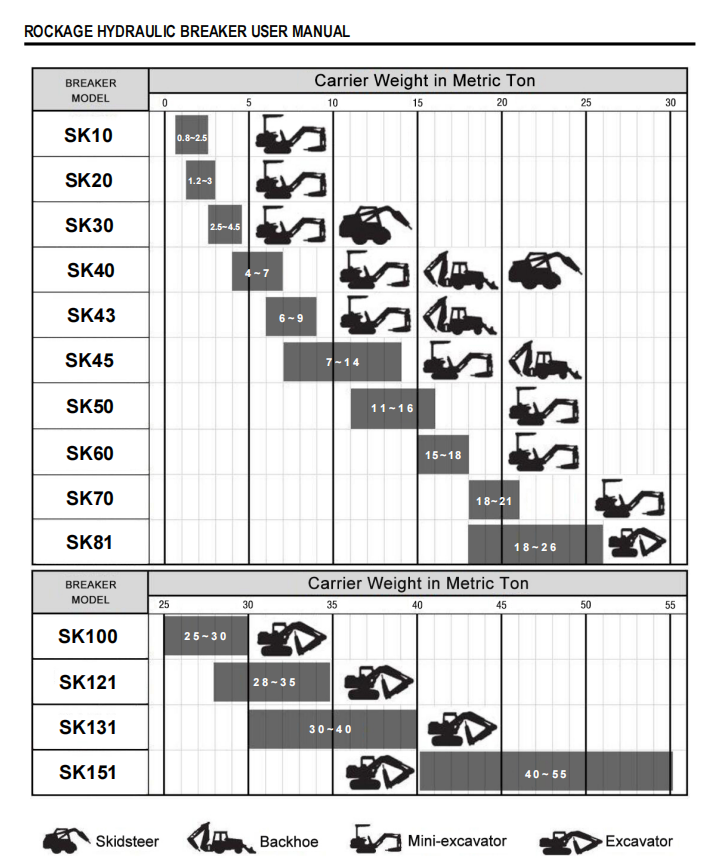

By using the Carrier Sizing Chart below, you can narrow your hammer choice. Normally breaker

production rate is the most crucial factor when trying to choose a breaker size. It is of great benefit to do

some research and understand your hydraulic system capabilities and the material size and hardness

before determining an expected production rate. This rate will also be affected by breaking conditions

and the operator.

Based on the Type of Work

The Production Rate is the next important factor to consider in sizing the breaker. Most situations call for

the largest breaker that your carrier could handle. The largest breaker is therefore the one to choose. The

lifting capacity of your machine is then the limiting factor. The carrier must be able to safely handle the

breaker at any distance out from the machine where you might be working.

Small Breakers

Smaller sized breakers up to 1,000 ft·lb class (1350 joule) are typically used in concrete and other light

duty work.

Medium Breakers

Medium sized breakers 1,500-4,000 ft·lb class (2000-5400 joule) are used in both concrete and rock

applications with limitations on the size and amount of material to be broken.

Large Breakers

Larger breakers greater than the 4,000 ft·lb class (5400 joule) are typically used in hard rock, high

production applications.

Breaking Oversize

When breaking oversize material, the breaker is expected to break the material down quickly into multiple pieces. This

is optimum production. If the operator has to re-position the breaker towards the edge of the rock and gradually

downsize the material, the production rate slows down. To assess which breaker will effectively handle this application,

the size and hardness of the material must be known.

For example, if a 4 cubic yard piece of hard rock (20,000 psi or greater) needs to be broken in half, a 7,500 ft·lb

or larger breaker is required. If a 2 cubic yard piece of limestone (20,000 psi or less) needs to be broken in half,

a 3,000-5,000 ft·lb breaker is required.

Trenching

When trenching, the breaker is expected to fracture a solid mass of rock into manageable pieces. The size

of the material could be hundreds of cubic yards, and the energy will be quickly absorbed. This is why it

is recommended to work from a bench so the rock has somewhere to break out.

When trenching in limestone or medium hard rock, use a 3,000 -5,000 ft·lb breaker.

When working in hard material use a 7,500 -10,000 ft·lb breaker.

5

Related News